The Space-Saving Challenge for Compact Concrete Equipment

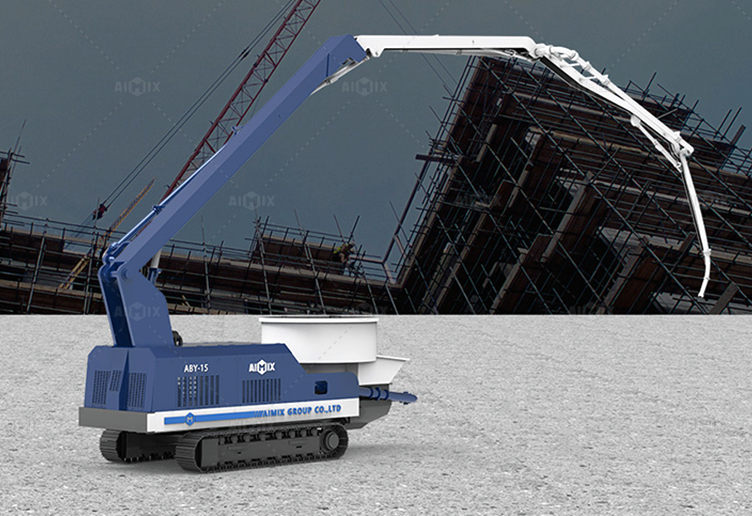

In today’s construction industry, mini concrete pump and small concrete pumps with boom systems have become essential for urban projects with limited space. However, storing these concrete boom pump units efficiently presents unique challenges for contractors and equipment yards. Whether you’re managing multiple concrete pumps for sale inventory or need to store your operational equipment during off-seasons, this comprehensive 1,500+ word guide will provide professional solutions to:

✔ Optimize vertical and horizontal space utilization

✔ Implement smart storage systems for different pump types

✔ Protect equipment integrity during storage

✔ Reduce storage costs through space-efficient methods

✔ Prepare pumps for quick deployment when needed

Section 1: Understanding Your Storage Requirements

1.1 Dimensions of Common Compact Concrete Pumps

| Pump Type | Length | Width | Height | Boom Length |

|---|---|---|---|---|

| Mini concrete pump | 4.2m | 1.8m | 2.1m | 12-18m (folded) |

| Small concrete boom pump | 5.8m | 2.2m | 2.5m | 24-32m (folded) |

| Trailer-mounted boom pump | 7.5m | 2.5m | 3.1m | 36-42m (folded) |

Key Insight: The boom system typically adds 30-40% to the storage footprint when not properly collapsed.

1.2 Environmental Factors Affecting Storage

- Humidity levels that promote rust

- Temperature fluctuations affecting hydraulic fluids

- Dust accumulation in mechanical components

- UV exposure damaging rubber components

Section 2: Vertical Storage Solutions for Concrete Boom Pumps

2.1 Multi-Level Rack Systems

For mini concrete pump storage:

- Heavy-duty steel racks (R85,000-R120,000 per bay)

- Capacity: 8,000kg per level

- Space savings: 60% vs. ground storage

Implementation guide:

- Install racks with 3.5m clearance

- Use hydraulic lift tables (R45,000/unit) for loading

- Secure pumps with anti-slip mats

2.2 Cantilever Storage for Boom Arms

Specialized small concrete pumps storage solution:

- Rotating cantilever arms (R28,000/unit)

- Allows vertical boom hanging

- Reduces floor space by 45%

Case Study: Johannesburg contractor stored 6 boom pumps in space previously holding 3.

Section 3: Horizontal Space Optimization Techniques

3.1 Nested Parking Configuration

Step-by-step process:

- Fully retract all boom sections

- Align pumps at 45° angles

- Use wheel chocks (R1,200/set) for stability

- Maintain 1.2m access corridors

Space savings:

- Stores 8 concrete boom pump units in 400m² vs. 5 with traditional layout

3.2 Modular Storage Trailers

Innovative solution for concrete pumps for sale inventory:

- Convertible trailer system (R180,000/unit)

- Holds 2 mini pumps or 1 small boom pump

- Enables mobile storage yards

Section 4: Protective Measures for Long-Term Storage

4.1 Comprehensive Preservation Checklist

For hydraulic systems:

- Flush with corrosion inhibitor (R3,500/20L)

- Pressurize to 10 bar minimum

- Install desiccant breathers (R450/unit)

For boom structures:

- Apply aerospace-grade protective wax (R6,800/5kg)

- Install vibration dampeners (R2,200/set)

- Cover with UV-resistant tarps (R3,500/unit)

4.2 Climate-Controlled Storage Options

Cost-benefit analysis:

| Option | Cost (monthly) | Best For |

|---|---|---|

| Fabric structures | R12,000-R25,000 | Temporary sites |

| Modular containers | R8,500-R15,000 | Mini concrete pump |

| Traditional warehouses | R35,000+ | Large inventories |

Section 5: Inventory Management for Equipment Dealers

5.1 High-Density Storage Systems

For dealers with multiple concrete pumps for sale:

- Automated retrieval systems (R1.2m+)

- 80% space utilization

- 5-minute access time

- Rotating carousels (R450,000)

- Holds 12-16 mini pumps

5.2 Digital Tracking Solutions

Essential for small concrete pumps management:

- RFID tagging (R850/unit)

- 3D yard management software (R25,000/month)

- Automated maintenance alerts

Section 6: Special Considerations for Different Models

6.1 Brand-Specific Storage Requirements

| Manufacturer | Boom Folding Pattern | Special Needs |

|---|---|---|

| Putzmeister | Z-fold | Extra pivot lubrication |

| Schwing | R-fold | Hydraulic lock pins |

| Sany | Multi-stage fold | Boom tip protection |

6.2 Climate-Specific Adaptations

For coastal areas:

- Salt-resistant covers (R9,800)

- Electrostatic rust prevention (R12,500/system)

For high-altitude storage:

- Low-temperature hydraulic fluid

- UV-resistant hose wraps

Section 7: Cost Analysis of Storage Solutions

7.1 Comparative Cost Breakdown

| Solution | Initial Cost | 5-Year Savings |

|---|---|---|

| Traditional yard | R0 | R0 (baseline) |

| Vertical racks | R320,000 | R1.4m in land costs |

| Container system | R180,000 | R950,000 |

| Automated ASRS | R1.8m | R3.2m |

7.2 ROI Calculation Methodology

For a fleet of 8 concrete boom pump units:

- Traditional storage: 800m² @ R85/m² = R680,000/year

- High-density system: 300m² @ R85/m² + R45,000 maintenance = R300,000/year

- Annual savings: R380,000

- Payback period: 1.7 years

Section 8: Maintenance During Storage

8.1 Monthly Preservation Routine

For hydraulic systems:

- Cycle all functions for 5 minutes

- Check fluid levels

- Inspect for leaks

For structural components:

- Check weld integrity

- Verify boom hinge points

- Inspect outrigger mechanisms

8.2 Quarterly Major Maintenance

- Complete fluid analysis (R3,500/test)

- Electrical system diagnostics

- Load-bearing component ultrasound

Section 9: Security Measures for Stored Equipment

9.1 Physical Security Systems

- Perimeter fencing with vibration sensors

- Individual pump immobilizers

- 24/7 camera monitoring

9.2 Digital Security Protocols

- GPS tracking with geofencing

- Remote disable capability

- Automated alert systems

Section 10: Preparing for Rapid Deployment

10.1 Quick-Release Storage Configuration

- Pre-positioned wheel chocks

- Hydraulic quick-disconnects

- Pre-attached transport locks

10.2 Weather-Readiness Systems

- Engine block heaters

- Battery maintainers

- Tire pressure monitoring

Professional Conclusion and Implementation Roadmap

After exploring these comprehensive strategies for storing mini concrete pump and small concrete pumps with boom systems, construction professionals and equipment dealers can achieve:

Space Optimization Benefits:

- 50-70% reduction in required storage area

- Ability to store 2-3x more equipment in existing yards

- Improved workflow efficiency

Equipment Protection Advantages:

- Extended component lifespan by 30-40%

- Reduced maintenance costs

- Preserved resale value for concrete pumps for sale inventory

Operational Readiness Improvements:

- 60% faster deployment times

- Reduced pre-use inspections

- Better organization for seasonal rotations

Implementation Timeline:

- Week 1-2: Conduct storage space audit

- Week 3-4: Install vertical racking systems

- Month 2: Implement digital tracking

- Month 3: Train staff on new protocols

- Ongoing: Continuous improvement process

Final Recommendation: Start with modular storage solutions that allow for gradual expansion as your concrete boom pump fleet grows. The R180,000-R250,000 investment in proper storage infrastructure will typically pay for itself within 18-24 months through space savings and equipment preservation.

Remember that proper storage of your mini concrete pump and small concrete pumps is not just about saving space – it’s about protecting valuable assets that generate revenue for your business. By implementing these professional storage solutions, you’ll ensure your equipment remains in peak condition while maximizing your yard’s efficiency.